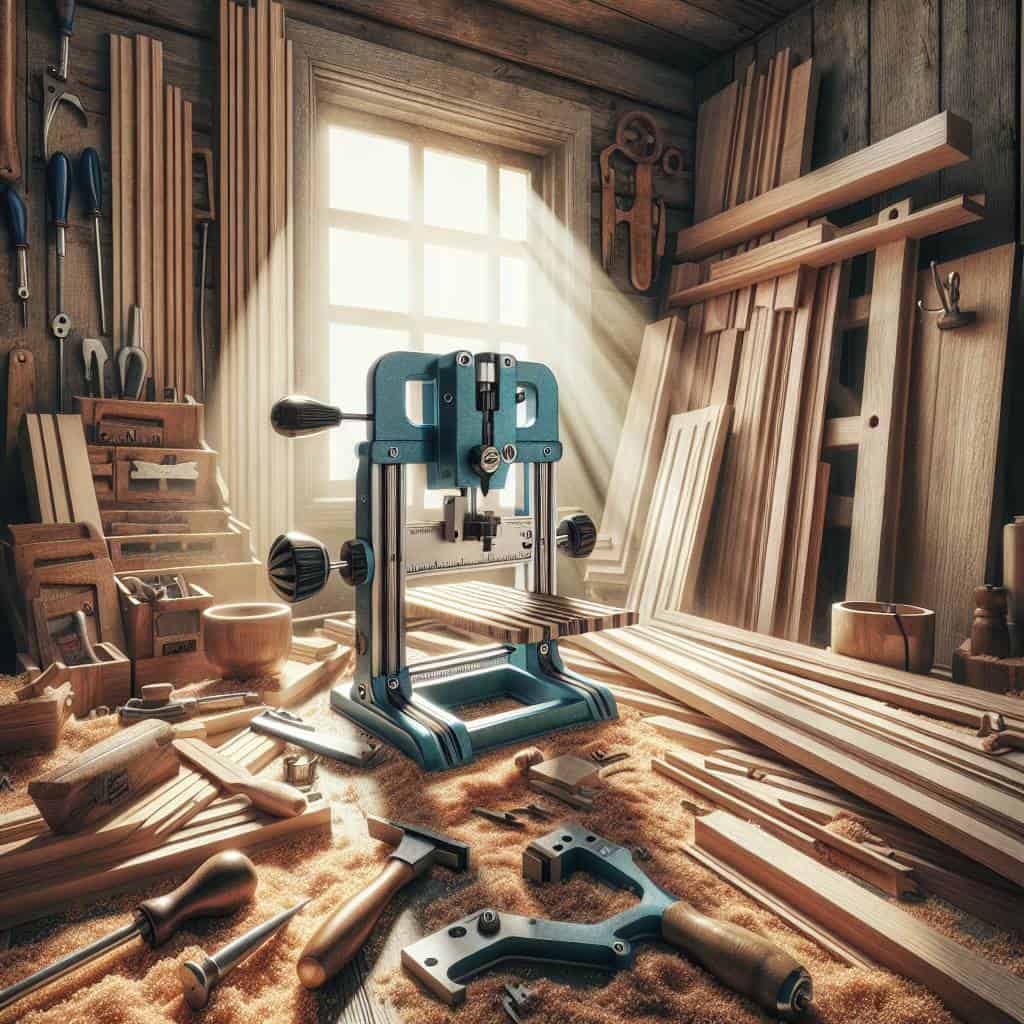

The first time I laid eyes on a Kreg pocket hole jig, I was knee-deep in sawdust and self-doubt, trying to piece together a rickety bookshelf that looked more like a Picasso sculpture. There it sat, blue and sleek like a beacon of hope amidst my chaotic workshop. “How hard could it be?” I muttered to myself, the same foolish optimism that once led me to believe I could replace my car’s carburetor with nothing but a YouTube video and sheer willpower. Spoiler alert: it was harder than it looked, and my first attempt at pocket holes resembled something closer to Swiss cheese than fine joinery. But there’s a charm in wrestling with a tool that promises to make the impossible possible, even if it means a few missteps along the way.

In this article, I’ll take you on a journey through the world of the Kreg pocket hole jig—a contraption that promises to make woodworking as easy as pie, or at least as easy as not burning the crust. We’ll dive deep into its quirks and promises, comparing the K4 and K5 models, and exploring the art of strong, invisible joints. Whether you’re a seasoned woodworker or someone who’s still figuring out which end of the hammer to hold, I’ll share what I’ve learned, and maybe, just maybe, save you from a few splinters and misguided holes. Buckle up, my friends, as we navigate the wood grain of this story together.

Table of Contents

The Tale of Two Jigs: K4 vs. K5 and My Quest for Strong Joints

In the dusty corners of my workshop, where sawdust settles like snow and the aroma of fresh-cut lumber lingers, my journey for crafting strong joints began with two steadfast companions: the K4 and K5 jigs. Each jig, a marvel of simplicity, promised to transform the way I joined wood. The K4 was my first dance partner in the waltz of woodworking joinery. It had all the charm of a reliable old friend—simple, straightforward, and unassuming. With the K4, I discovered that creating pocket holes was as easy as pie—provided you didn’t mind a little elbow grease. Every time I clamped a board into its sturdy embrace, it felt like shaking hands with an old farmer who knows his craft inside out.

But then came the K5, strutting onto the scene like a city slicker with a bit more polish and a few more gadgets. The K5 took everything I loved about the K4 and added a touch of finesse. With its adjustable clamp and dust collection port, it promised not just strong joints, but a cleaner, more efficient process. I found myself torn between the K4’s raw simplicity and the K5’s refined efficiency. Each jig had its place in my quest for woodworking nirvana, offering different paths to the same end: joints that could withstand the test of time and tide. As I navigated the nuances of each tool, I realized that, much like life, the journey was as crucial as the destination, and the tools we choose to bring along shape our stories in unexpected ways.

The Unseen Art of the Pocket Hole

In the dance of wood and steel, the Kreg pocket hole jig is the quiet partner, ensuring every joint holds its rhythm without missing a beat.

The Last Turn of the Screw

In the end, the Kreg pocket hole jig—whether it’s the K4 or the K5—is more than just a tool. It’s a rite of passage for anyone looking to make woodworking more than just sawdust and splinters. It’s like finding your rhythm on a dusty back road, where each turn and twist becomes a little less daunting and a lot more satisfying. Sure, there were moments I wanted to chuck it out the window in frustration, cursing under my breath about how ‘easy’ it was supposed to be. But as I stood back, admiring the sturdy joints that quietly whispered tales of perseverance and a few colorful expletives, I realized that the journey with these jigs was, in itself, a kind of joinery—piecing together patience, skill, and a touch of grit.

The K4 and K5, they’re not just entries in a catalog. They’re chapters in a story that’s still being written with every project and every plank. As I close the lid on this particular tale, my hands are a bit rougher, my mind a bit sharper. I’ve learned that the real strength in joinery doesn’t just come from the tools we wield but from the stubborn refusal to let a crooked board or a misaligned hole get the best of us. So here’s to the next project, the next challenge, and the next lesson that awaits in the sawdust-covered pages of this ever-turning adventure.